-

Fiber Optic Patch Cables

-

MPO Trunk Cable

-

MTP Trunk Cable

-

MPO Patch Panel

-

Fiber Optic Pigtail

-

Fiber Optic Splitter

-

Fiber Distribution Box

-

FTTH Products

-

ODF Patch Panel

-

Fiber Terminal Box

-

Fiber Optic Adapter

-

Fiber Optic Connectors

-

Fiber Optic Attenuator

-

Fiber Optic Closure

-

Fiber Optic Tools

-

Fiber Optic Cable

-

LenaThanks for OMC's Gifts. that's very nice. WE are expecting a better 2019

LenaThanks for OMC's Gifts. that's very nice. WE are expecting a better 2019 -

HassanI like quality. It will be better if better package. but their price is very good. Maybe i will pay more to get a better package

HassanI like quality. It will be better if better package. but their price is very good. Maybe i will pay more to get a better package -

PaoloFastest delivery, that's very good.

PaoloFastest delivery, that's very good.

Light Armored Stranded Loose Tube Cable GYTS PBT Black 24 - 144cores

| Place of Origin | China |

|---|---|

| Brand Name | OMC or OEM |

| Certification | ROHS and ISO |

| Model Number | Standard Loose Tube light-armored Cable (GYTS) |

| Minimum Order Quantity | 20 |

| Price | Negotiation |

| Packaging Details | Inner PE Bag and carton |

| Delivery Time | 5 - 8 work days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 1000/pcs/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Number Of Fiber | 24-144cores | Moisture Barrier | Water Blocking System |

|---|---|---|---|

| Material(Loose Tube) | PBT | Diameter(Loose Tube) | Ф2.2(outer/inner) |

| Material(Outer Sheath) | PE/HDPE | Diameter(Outer Sheath) | 1.70±0.2mm |

| High Light | PBT Black stranded loose tube cable,stranded loose tube cable GYTS,Armored stranded loose tube cable |

||

Description:

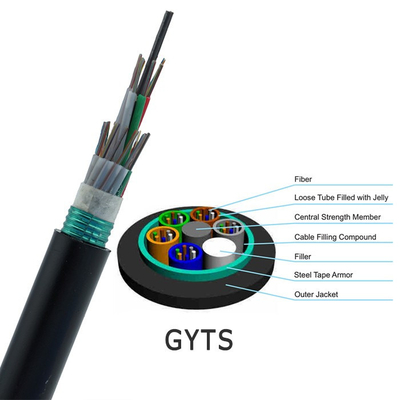

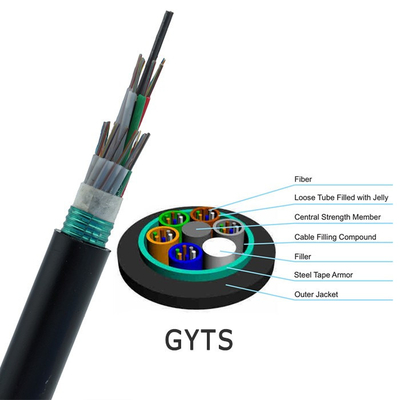

Steel Tape Layer Loose Tube Outdoor Cable GYTS

1. Cable Description:

The fibers, single mode or muti mode, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath.

2.Cable Drawing:

![]()

<Cross-sectional Drawing of Cable>

![]()

Note : Structure drawing just for reference, please check the following details.

3. Application:

Adopted to outdoor distribution;

Suitable for aerial, pipeline laying method;

Long distance and local area network communication.

4. Characteristic.

Good mechanical and temperature performance

High strength loose tube that is hydrolysis resistant

Special tube filling compound ensure a critical protection of fiber

Crush resistance and flexibility

PE sheath protects cable from ultraviolet radiation

The following measures are taken to ensure the cable watertight:

Steel wire used as the central strength member

Loose tube filling compound and 100% cable core filling

PSP enhancing moisture-proof

5.Features:

5.1 Fiber Allocation Scheme

| Fiber number | Tube number | Fiber per tube | Fiber type |

| 24-144 | 1-12 | 12F/Tube | OS1,OS2,OM1,OM2, OM3,OM4 |

5.2 Cable construction details

| Items | Description | |

| Number of fiber | 24-144cores | |

| Moisture Barrier | Water blocking system | |

| Central strength member | Material | Steel wire/FRP/FRP with PE cover |

| size | 1.4mm | |

| Loose tube | material | PBT |

| diameter | Ф2.2(outer/inner) | |

| Tube-filling | material | Tube filling compound |

| Armoring | Material | Corrugated steel tape |

| Outer sheath | material | PE/HDPE |

| diameter | 1.70±0.2mm | |

6.Standand colour of fiber and tube:

The color code of the tubes and the individual fibers, shall be in accordance with the table as below:

| Standard Colour Identification | |||||||

| No. | 1 | 2 | 3 | 4 | 5 | 6 | |

| Color | Blue | Orange | Green | Brown | Slate | White | |

| No. | 7 | 8 | 9 | 10 | 11 | 12 | |

| Color | Red | Black | Yellow | Violet | Pink | Aqua | |

7. Cable Mechanical Characteristic:

| Items | Cable diameter | Weight | |

| 2 cores to 30 cores | 8.6±0.5mm | 105±5kg/km | |

| 48 cores | 9.6±0.5mm | 115±5kg/km | |

| 72 cores | 10.5±0.5mm | 125±5kg/km | |

| 96 cores | 12.2±0.3mm | 180±5kg/km | |

| 144 cores | 14.9±0.5mm | 245±5kg/km | |

| Installation Temperature range | -15--+60℃ | ||

| Operation and transport temperature | -40-+70℃ | ||

| Min Bending Radius(mm) | Long term | 10D | |

| short term | 20D | ||

| Allowable Tensile Strength(N) | Long term | 600 | |

| short term | 1000 | ||

| Crush Load (N/100mm) | Long term | 300 | |

| short term | 1000 | ||

8. Requirement for Order:

1.Fiber sort: Single mode G652,G655,G657, Multi mode 50/125,62.5/125,OM3,OM4.

2.Fiber brand: YOFC, Corning, Fiberhome Fujikura, OFS etc.

3.Sheath material: PE,LSZH( can be required).

4.Sheath color: Black ,can be required.

5.The fiber and tube color: according to stranded color, can be required.

6.The cable Size: shall be in accordance with the table, can be required.

7.Length of cable: generally is 2KM, can be required.

8.Other requirement:can be negotiated.

9. Fiber characteristic

| Fiber style | Unit |

SM G652D |

MM 50/125 |

MM 62.5/125 | ||

| condition | nm | 1310/1550 | 850/1300 | 850/1300 | ||

| attenuation | dB/km | ≤0.36/0.23 | ≤3.0/1.0 | ≤3.0/1.0 | ||

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ..... | ..... | |

| 1550nm | Ps/(nm*km) | ≤22 | ..... | ..... | ||

| Bandwidth | 850nm | MHZ. KM | ..... | ≧400 | ≧160 | |

| 1300nm | MHZ. KM | ..... | ≧800 | ≧500 | ||

| Zero dispersion wavelength | nm |

≧1302, ≤1322 |

..... | ..... | ||

| Zero dispersion slope | nm | ≤0.091 | ..... | ..... | ||

| PMD Maximum Individual Fiber | ≤0.2 | ..... | ..... | |||

| PMD Design Link Value | Ps(nm2*km) | ≤0.08 | ..... | ..... | ||

| Fiber cutoff wavelength λc | nm | ≧1180,≤1330 | ..... | ..... | ||

| Cable cutoff wavelength λcc | nm | ≤1260 | ..... | ..... | ||

| MFD | 1310nm | um | 9.2±0.4 | ..... | ..... | |

| 1550nm | um | 10.4±0.8 | ..... | ..... | ||

| Numerical Aperture(NA) | ...... | 0.200±0.015 | 0.275±0.015 | |||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.10 | ≤0.10 | ||

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.10 | ≤0.10 | ||

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.08 | ≤0.10 | ||

| Attenuation uniformity | dB/km | ≤0.01 | ....... | ....... | ||

| Core diameter | um | ...... | 50±1.0 | 62.5±2.5 | ||

| Cladding diameter | um | 125.0±0.1 | 125.0±0.1 | 125.0±0.1 | ||

| Cladding non-circularity | % | ≤1.0 | ≤1.0 | ≤1.0 | ||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | ||

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | ||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ||

| Core/cladding concentricity error | um | ≤0.6 | ≤1.5 | ≤1.5 | ||

| Curl(radius) | um | ≤4 | ..... | ..... | ||

10. Cable marking and cable reel marking

10.1 Cable marking

The cable sheath shall be marked with white characters at intervals of one meter with following information:

1. Purchaser’s name

2. Cable type

3. Fiber type and counts

4. Year of manufacture

5. Length marking

Notice: cable mark is available if requested by customer.

10.2 Cable reel:

Details given below shall be marked with a weather materials on both outer sides of the reel flange :

1. Cable type and fiber counts

2. Length of cable in meters

3. Year of manufacture

Notice: shipping mark is available if requested by customer.

![]()

11. Packing Informations

1. Packing material: Wooden drum

2. Packing length: standard length of cable shall be 2 km. Other cable length is also available if required by customer

12. Our certificates :

1) ISO9002

2) SGS, ROHS

3) ULE329066

4) REACH

13. Testing Lab:

| No | Device name | No | Device name |

| 1 | Optical time domain reflectometer (OTDR) | 8 | GNZV Cable Torsion Testing Machine |

| 2 | Fiber Polarization Mode Dispersion | 9 | GQNV Cable Flexing Testing Machine |

| 3 | Fiber Dispersion ,Strain Tester | 10 | GJRV Cable Winding Testing Machine |

| 4 | High Low Temperature Test Chamber | 11 | GZDV Cable Vibration Testing Machine |

| 5 | Cable Impact Testing Machine | 12 | Cable Water Penetration Test |

| 6 | Cable Squash Tensile Testing Machine | 13 | Fusion Splicer |

| 7 | GWQV Cable Bending Tester | 14 | Cable Water Penetration Test Rig |

Fiber Optic Cable Mechanical Performance Testing Laboratory

1. Main Testing Type: Precision Test and Mechanical Test.

2. Precision Testing Machine: EXFO OTDR, EG&G PMD-440,CD-400.

3. Mechanical Performance Testing : Temperature, Impact, Tensile, Bending, Torsion, Flexing, Winding, Vibration, Water Penetration, Fusion Splicer, Water Penetration.

14. Our advantages:

1. Professional cable manufacturer.

2. About 10 years experiences in cable industry.

3. MOQ just 1Km.

4. ISO, UL , ROSH,REACH...certifications.

5. Can be customized production of fiber optic cable.

6. Independent Lab with full set of testing machines.

15. Our factory: